Test and verify inventory

When you first start using your Byte Technology store, you'll need to test how you'll be tagging products and how you'll be merchandising those products. Proper tagging and merchandising are critical to ensuring your Byte store is able to read inventory appropriately.

Follow these steps to run a test:

- Tag the products you will be testing following tagging best practices

- Use your login to access the restocker panel, unlock the store, and place tagged products following merchandising best practices

- Exit the restocker panel on the store

- Confirm the inventory is properly read in the Byte Technology Dashboard under Stores > Restock. See below for how to check the online dashboard for inventory count and accuracy:

If the product disappears from inventory, this is an indicator that tagging can be improved. Inventory reports are only as accurate as the RFID readings of the store itself. When first getting started with a new Byte store or a new product, it is important to test out the placement and readability of the tags on your product.

Steps to take if inventory is still not reading accurately:

- Check that the last restock was done in restocker mode. If the Door Open command was used to restock the store, there is a high chance of inventory discrepancy. This can be fixed by someone going into restocker mode, opening and closing the door and then exiting restocker mode.

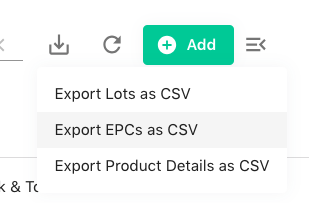

- Download the EPC report (This can be found in the Products tab > select the Export Icon > select Export EPCs as CSV.

- Review the report. This report will show you all RFID tags (found under the EPC column) that are presently reading in your store.

- Compare EPCs from the report to what is in your store, the EPCs (RFID tags) that are not in found will need to be replaced with a new tag or re-situated.

We would recommend you check on the placement of these products to resituate the tags so that the following occur:

- The tag is not hidden among the products

- All merchandising best practices are followed.

- All flag tags are folded correctly and are up and off the product. Please refer to this article about how flag tags should look.

- The tags are not touching other products.

- Tags are not in direct contact with metal or liquid (this includes yogurt and sauces

Please refer to our articles regarding proper merchandising and tagging to help with the needed changes:

- Best Tagging Practices

- Tagging Drinks

- Tagging Salads

- Tagging soups/yogurts

- Tagging heatable products

- Tagging Sandwiches

- Tagging Aluminum Products

- Best Merchandising Practices

Byte Support Help Needed

After attempts to correct tagging and product placement, if you find yourself continuing to have issues with getting inventory correct, please gather the following information before reaching out to Byte Support.

- Pick a date and time that this information is current ex. Wed 10.11.2020 at 12 PM noon EST- List KID/name of the store you are looking at ex. KID 2345 Name Byte Tech HQ

- Count how much of each SKU is physically in the Byte store (you can pick 1 or two of the SKUs you are seeing the most, ex. a specific drink OR meal)

- Take a photo of the tags of that product that are in the Byte store - specifically looking for that long serial number that looks like this 000102680116032135970039

Important to Note Regarding Testing Tags

Metal Tag Read Sensitivity In March 2020 Byte Technology launched several new RFID tag types in order to support our clients with a broader range of product types. The new tag types included microwave-safe tags and metal-safe tags. The metal safe tags were a recent and exciting innovation from Byte Technology’s tag partner. Before launching these new tags in the marketplace, Byte Technology partnered to test the tags on a range of product types. The initial tests noted that the tags performed equal to or better than the existing set of Byte Technology tags, so we proceeded to launch. While the pandemic delayed learnings about these new tag types, it is now evident that metal-safe tags are very sensitive to how they are applied, as well as how the products are merchandised within the fridge. When these conditions are met, the tags appear to perform as expected. Byte Technology is currently doing more extensive testing, but early findings show:

- Tags separated by distance and not touching other products perform better. Dividers that space product may result in improved readability performance

- Tags appear to perform better when facing away from one another. When tags are close to one another they appear to cause more “scatter” which makes it hard for sensors to properly read inventory. Rotate drinks or products to maximize the space between other tags: